Exploring the World’s Largest Cricket Stadium: Discovering the profound structural importance and unparalleled architectural distinctiveness

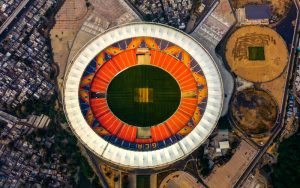

The Narendra Modi Stadium in Gujarat, India, is indeed an iconic structure and holds the title of being the world’s largest cricket stadium. It is a magnificent example of an architectural marvel that showcases the effective use of steel structure. The Narendra Modi Stadium in Gujarat, India, is undoubtedly a remarkable architectural masterpiece. Boasting the title of the world’s largest cricket stadium, it stands as a testament to human innovation and engineering prowess. One cannot help but be captivated by its grandeur and magnificence. The effective use of steel structure is truly commendable, lending strength and durability to this iconic landmark. It not only showcases impeccable design principles but also ensures that the stadium can accommodate thousands of spectators while providing unobstructed views of the game. The sheer scale of this structure leaves visitors in awe as they marvel at its vastness and precision. From every angle, one can appreciate the intricate details that have been meticulously incorporated into its construction.

Moreover, beyond its impressive physical attributes, the Narendra Modi Stadium holds great cultural significance for cricket enthusiasts worldwide. It has become a symbol of national pride for India and serves as a venue where countless memorable moments have unfolded on the cricket field. Whether you’re an ardent sports fan or simply an admirer of architectural brilliance, visiting the Narendra Modi Stadium is an experience like no other. It’s a testament to human ingenuity and serves as a reminder that with determination and vision, we can create structures that leave an indelible mark on our collective consciousness. In conclusion, the Narendra Modi Stadium stands tall as an unrivaled example of how effective steel structures can transform dreams into reality. Its status as the world’s largest cricket stadium further solidifies its place in history while captivating all those who have had the privilege to witness its grandeur firsthand.

Image Credit GCA

The Narendra Modi Stadium in India has recently claimed the title of the largest stadium in the world. This remarkable achievement is even more impressive considering that it was a renovation project, originally envisioned to become the grandest stadium on earth. The renovation of this stadium commenced in 2017 and was successfully concluded in 2020, transforming it into a state-of-the-art facility. Today, it proudly stands as a fully functional stadium, managed and administered by the esteemed Gujarat Cricket Association.

The remarkable transformation of this stadium is a testament to the visionary leadership of Indian Prime Minister Shri Narendra Modi. In just three short years, his vision became a reality, culminating in the grand inauguration on 24th February 2020. With a seating capacity for up to 11, 000 cricket enthusiasts at once, this stadium stands as a beacon of sporting excellence. Not only does it boast state-of-the-art facilities such as an Olympic size pool and three practice grounds, but it also offers top-notch amenities including dressing rooms, an indoor cricket academy, and even 76 corporate boxes for VIP guests. This truly showcases the commitment to providing an unparalleled experience for all who visit. Under the guidance of Prime Minister Shri Narendra Modi’s vision and dedication, this reconstructed stadium has become a shining example of what can be achieved in a relatively short amount of time. Its impressive features and attention to detail make it a true gem in India’s sports infrastructure landscape.

This stadium has successfully achieved a gold rating under the IGBC’s esteemed ‘Green new building rating system’. In addition to its environmental friendliness, another notable aspect is its cost. Considering the impressive quality and scale of the project, it was completed at a relatively affordable budget of approximately $102 million, highlighting an excellent return on investment.

The construction of this magnificent stadium was entrusted to Larsen and Toubro (L&T), known for their expertise in delivering exceptional projects. Not only is it the largest stadium, but it also boasts a state-of-the-art architectural design that captures attention. The structural design is truly impressive, with Walter P Moore, a highly skilled structural engineer, leading the conceptualization and implementation of the intricate plan. The roof system stands out as one of the most remarkable features, showcasing the ingenuity and innovation involved in its creation.

Populous, a renowned architecture firm, came up with an innovative design for the upper bowl of the stadium – a concept known as the tensile fabric roof. To bring this concept to life, they collaborated with Walter P Moore, a leading structural engineering company. Given that Ahmedabad is located in a level 3 seismic zone, it was crucial to create a lightweight roof system that could minimize seismic demand and be cost-effective. The team devised a seismically independent tensile fabric roof system that is separate from the concrete seating bowl. To provide sturdy support, steel “V” shaped columns were strategically installed. These columns not only bear gravity loads but also effectively absorb lateral forces caused by strong winds and earthquakes. By implementing this groundbreaking solution, Populous and Walter P Moore have created an architectural marvel that ensures safety while maintaining an aesthetically pleasing design for the stadium.

Given the three-tier system in place, it was essential to design the roof system accordingly. Each tier is structurally independent, a feature specifically implemented due to the stadium’s location in a level three seismic zone. To ensure optimal safety and functionality, the roof had to be lightweight and completely separate from the bowl structure.

Moore came up with an ingenious solution to simplify the erection process and reduce costs. He proposed a flexible compression system that utilized a Teflon-coated, woven fiberglass material known as PTFE. This material was strategically placed between an inner tension ring and an outer compression ring, allowing the entire structure to adapt to any seismic activity. By incorporating cable spokes, the rings were able to float in the middle of the bowl and roof, ensuring freedom of movement while maintaining stability. This innovative approach not only made construction easier but also provided significant cost-saving benefits.

According to Viral Patel, the Director of Design at Walter P Moore, the seismic forces are directly related to the mass of the structure. With this in mind, they wisely chose to incorporate a lightweight structure with a cable tensile roof from the very beginning. Additionally, they made a strategic decision to keep the roof system and concrete bowl separate from each other. This careful planning ensures both structural integrity and flexibility for optimal performance.

Design head of L&T construction, Mr. R Eswaran said

“We constantly challenge our engineering capabilities by strategizing to develop unique designs that not only perform well when executed but also contribute to the world of engineering by adopting the latest technologies. The Motera Stadium is a prime example of our commitment. Our engineering and execution teams work in constant coordination to accomplish these monumental tasks. We highly value teamwork and celebrate success. This project serves as our tribute to the nation, and we take great pride in our contribution.”

Double Curve Facade

The complexity of the facade’s three-dimensional profile was efficiently achieved through the utilization of advanced software. The structure’s framework consists of bent steel tubes meticulously crafted into a 3D shape, while the exterior surface is divided into sections made from precision-cut aluminum sheets. This innovative process leverages computerized cutting machinery to ensure precise shaping and profiling.

https://gujaratcricketassociation.com/narendra-modi-stadium/

Precast segments

Designing the stadium was no easy feat, especially when it came to creating the upper bowl. This particular section posed a significant challenge due to its complex nature. To tackle this, geometric shape columns were employed, along with precast components that were an impressive 35 meters in length and weighed 285 metric tons. By utilizing these heavy-duty elements, not only were joint numbers reduced, but it also ensured a faster construction process without compromising on structural integrity.

Design concept of the stadium

The stadium’s construction is a meticulously planned process, with each section carefully designed through brainstorming sessions. A sectional view of every zone is created to ensure efficient planning and execution. Various perspectives of the stadium are considered, including zone-wise divisions, lower and upper bowl plans for seating arrangements, as well as detailed sectional views of VIP areas and other relevant divisions. This comprehensive approach guarantees a well-organized and functional stadium layout.

https://gujaratcricketassociation.com/narendra-modi-stadium/

Constructional methodology of the project

The construction project is benefitting from the implementation of the precast methodology. To ensure efficiency and precision, the structural aspect of the construction was completed in eight distinct phases. Throughout each phase, careful attention was given to address all technical aspects. The precise positioning required for the project was thoroughly planned and executed accordingly.

What are the challenges faced in the entire reconstruction of an existing stadium?

-

Undertaking the transformation of a 35, 000-capacity stadium into a colossal venue accommodating approximately 110, 000 spectators was no easy feat. The first step involved designing an innovative elliptical shape with intricate architectural details and a robust structure. To ensure both efficiency and speed in construction, the project utilized precast technology, taking into consideration the immense scale of the endeavor.

What is the technology used for completing this huge project in time?

-

The stadium’s unique charm lies in its distinct ‘Y’ columns, each measuring 2. 7m in length, towering at 30m in height, and weighing a staggering 285 tonnes. These remarkable columns were skillfully transported and meticulously erected at the project site. To ensure flawless execution of the fabric design, steel structure, and cables, the structural steel roof was fortified with PTFE fabric and pre-stressed cables. This combination not only adds to the overall aesthetics but also guarantees durability and reliability for years to come.

-

Constructing the roof was no easy feat. With a perimeter of 1000m, a towering truss height of 10. 5m, and an impressive 30m cantilever, it posed quite the challenge. The location added an extra layer of complexity, surrounded by residential complexes. Despite these obstacles, the planning was meticulously carried out to ensure success. And let’s not forget about the tremendous effort put into transporting materials and machinery to make this ambitious project a reality.

What were the architectural references used in the designing process?

-

The concept behind the stadium’s design draws inspiration from the renowned Melbourne Cricket stadium. The objective was not only to create the largest stadium but also to match up to its exceptional standards. Every aspect, including size, features, and facilities, had to be on par. Ensuring an outstanding visual experience for spectators was a top priority, which is why a 360° view was a crucial requirement.

1. Size and Capacity: With a seating capacity of over 130,000 spectators, the stadium offers an unparalleled experience for cricket enthusiasts. Its vast size allows for a grand atmosphere during matches and events.

2. Steel Structure: The extensive use of steel in the stadium’s construction provides various advantages. Steel offers high strength, durability, and flexibility, allowing for the creation of large spans without compromising structural integrity. It also enables efficient construction and faster project completion.

3. Roof Design: The stadium features a unique and innovative roof design that ensures maximum coverage while minimizing shadows on the playing field. The steel roof structure supports the large expanse, providing shade and protection to spectators while maintaining an open and airy feel.

4. Aesthetics: The Narendra Modi Stadium‘s design is visually striking, with clean lines and a modern aesthetic. The steel structure enhances its architectural appeal, creating an iconic landmark that represents both Gujarat and India on a global scale.

5. Multi-Purpose Facility: The stadium’s versatile design allows it to host various sporting and non-sporting events. It can accommodate not only cricket matches but also other activities like concerts, exhibitions, and cultural events, making it a true multi-purpose facility.

6. Facilities and Amenities: The stadium offers top-notch facilities and amenities for players, officials, and spectators. It includes state-of-the-art dressing rooms, media boxes, VIP lounges, corporate boxes, food courts, and ample parking, ensuring a comfortable and memorable experience for all.

The Narendra Modi Stadium in Gujarat, with its impressive steel structure and architectural design, has become a symbol of excellence in sports infrastructure. It showcases India’s commitment to creating world-class sporting venues and contributes to the growth and development of cricket in the country.

When undertaking large-scale projects, it is crucial to have an exceptional team with a strong vision and an unwavering passion for CAD drafting and BIM modeling. This ensures that only the highest quality work is delivered. In the architectural industry, Structural Drafting India has established itself as one of the top players, renowned for its expertise and innovation.

Our firm specializes in handling large-scale projects by delivering a wide range of drafting, modeling, and rendering services. With an experienced team of dedicated professionals, we ensure top-quality work that meets the highest standards. Our skilled personnel are passionate about delivering excellence in every aspect of our projects.

From skyscrapers to hospitals, educational institutions to airports, stadiums and beyond – we have successfully tackled diverse construction ideas over the years. Our expertise is evident through the consistent level of service we have provided throughout our journey.